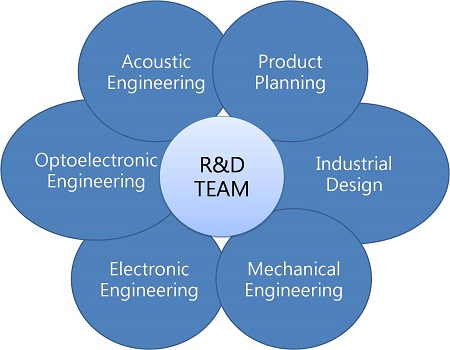

R&D Team

RD team of FORESHOT have Product Planning、Industrial Design、Mechanical Engineering、Electronic Engineering、Optoelectronic Design、Acoustic Engineering for Plastic Injection Molding and EMS(Electronics Manufacturing Services).

FORESHOT founded in 1985 has more than 40 years of experience in the plastic injection molding industry. In order to provide customers with more professional services, Hong Plastics integrates upstream and downstream supply chains, provides OEM/ODM service solutions and continues to develop new technologies. Services cover mold design and manufacturing, plastic injection molding, metal stamping, product assembly, etc. to final product mass production, providing customers with satisfactory quality and services. The technology is applied to 3C products, electronic parts, medical equipment parts, optical parts, and automobile and motorcycle parts.

According to various needs of customers, FORESHOT can provide design suggestions in advance to help customers optimize product structure. In the development process of plastic and metal parts, we can provide customers with improved optimized design, improve product defect rate and mass production, and save unnecessary development costs.

FORESHOT R&D technology covers electroacoustics, optoelectronics, electronics, mechanisms, industrial design, product planning and other services. Hongsu is committed to cultivating professional technical talents. According to the characteristics of the product, it can combine professional R&D capabilities and mold design technology to efficiently complete products of various shapes or surface treatments, effectively improve the process and solve production technology problems.

In addition, we can provide product development and complete solutions to mass production, which satisfies the needs throughout the entire product manufacturing, achieves precise cost control, and utilize the maximum production capacity.

FORESHOT R&D TEAM have three parts:Research & Design Services、Technical Development Engineering、Manufacturing Engineering:

Foreshot R&D TEAM have three parts:Research & Design Services、Technical Development Engineering、Manufacturing Engineering:

.jpg)

Research & Design Services

● Product Planning: new product services including analysis, design, cost estimation and pricing, marketing planning, and integration of development flow.

● Industrial Design: product exterior design and color matching plan.

● Mechanical Engineering Design: structural designs of metal and plastic products, post machining processing of various parts, product test, and mold development.

● Electronic Engineering Design: circuit design, application integration, and testing of electronic product hardware.

● Optoelectronic Design: optical design of high brightness backlight module, optical design of LED packaging, and designs of automobile headlight and outdoor lighting.

● Acoustic Design: design and fabrication of electroacoustic devices and design of sound effect products.

Technical Development Engineering

● Assist clients in development analysis and study of new products.

● Assist clients in the development of manufacturing techniques of new products.

● Provide clients the solutions to address issues in process techniques.

● Research and development of plastic production technique (e.g., bonding technique and plastic forming).

Manufacturing Engineering

● Assist clients in the development and manufacturing of molds for new products.

● Assist clients to uncover the blind spots in structural design of products in advance to facilitate smooth and speedy development of mold and clips fixture and address related issues before moving to mass production.

● Provide clients with implementation of new techniques to new products.

● Provide the technique of production by automatic injection molding.

● Assist clients in testing, assembly, functional verification, problem solving and eventual introduction to mass production.

Top News

FORESHOT Received a Golden Award from SWISSCOM in 2025

FORESHOT Received a Golden Award from SWISSCOM in 2025Foreshot was awarded the 2025 Swisscom Golden Award for Sustainable Development, recognizing its exceptional achievements in environmental innovation, net-zero emission, and green supply...

Read More FORESHOT Received an Excellent Vendor Award from FOXCONN INDUSTRIAL INTERNET in 2025

FORESHOT Received an Excellent Vendor Award from FOXCONN INDUSTRIAL INTERNET in 2025Excellent Vendor Award from FOXCONN INDUSTRIAL INTERNET in 2025

Read More FORESHOT Got Greenhouse Gas Verification Opinion in 2024

FORESHOT Got Greenhouse Gas Verification Opinion in 2024Greenhouse Gas Verification Opinion in 2024

Read More