SMT & Electric Mechanical Parts

Apply in Plastic Injection Molding / Metal Stamping / SMT / Assembly Service

OEM/ODM of SMT & Electric Mechanical parts by Plastic Injection Molding and EMS(Electronics Manufacturing Services).

FORESHOT founded in 1985 has more than 30 years in plastic injection industry. In order to give customers more comprehensive service, FORESHOT integration of OEM/ODM and continue develop new technology. FORESHOT Service Including Molding Design, Plastic Injection Molding, Metal Stamping, Assembly Service to Final Product it's let customer satisfied.

In addition, R&D team is working on technology application and innovation for product integration and better productivity. What's more, FORESHOT insists to follow standards of international quality certification.

The technology service of FORESHOT are Plastic Injection Molding, Metal Stamping、SMT and Assembly Service, which are applied in SMT & Electric Mechanical Parts: IVD (In Vitro Diagnostic Devices).

- Related Products

LSR/LSM Injection Molding

LSR/LSM Injection MoldingOrganosilicone known as Silicone, it is a type of molecular chain and a non-breakable Polysiloxane that it's a silicon atom combined with oxygen atom.Silicone has various kinds of material、unique functions and wide range of uses. It's an indispensable chemical materials that also call 「technology development catalyst」. As shown below is material classification.

RHCM

Traditional plastic injection molding does often uneven surface gloss of products and floating or exposed fibers on the surface of the fiberglass reinforced plastic chassis、poor transferability、inject pressure excessive and inject pressure uneven that they make stress marks around the mold gate of the product.Therefore, it is necessary printing and painting process to cover these surface defects. For high gloss products, insufficient brightness and uneven brightness cannot be covered by painting.Therefore, FORESHOT develops and apply RHCM technology, not only solve the above problems but also solve traditional plastic injection molding in ultra-thin parts, thick parts and reduces the cycle time.RHCM (Rapid Heat Cycle Molding) is rapidly changing the temperature of mold in injection process.This process is not only vanish the welding lines of the surface, but also improve the rate of product gloss and higher mold transferability.High Gloss / Welding Line free Injection Molding with RHCM process is high-level technology, however, FORESHOT has been operated well in High Gloss / Welding Line free Injection Molding with RHCM process and invests many 250T ~ 1000T RHCM machines that they can do mass production and let customers satisfied.

SMT

Surface-Mount Technology (SMT) is a term for a relatively modern style of printed circuit board design. The vast majority of commercial electronics are all about complex circuitry fitting in small spaces. In SMT, instead of putting wire leads into holes drilled in the circuit board, components and elements are mounted directly onto the surface of the board. Due to its efficiency and effectiveness, SMT has widely replaced through-hole technology methods for constructing PCBs.FORESHOT provides One-Stop shopping service from material procurement to assembly service. FORESHOT also offers the services of grouping and machining of product processing such as SMT / DIP PCB grouping, spray painting and printing, product assembly, packaging, SMT Assembly,SMT Process, EMS(Electronic Manufacturing Services) and Electronic Components etc. In addition, we have test service for PCBA (Printed Circuit Board Assembly) and final goods test.

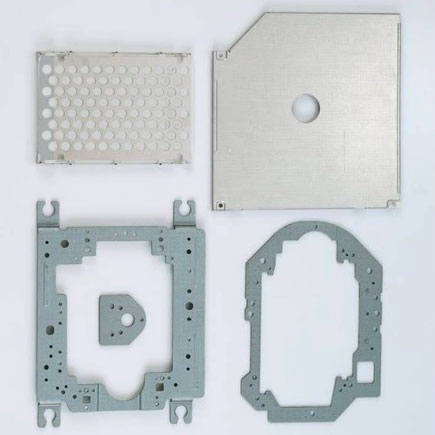

Metal Stamping

Metal stamping is an important manufacturing process its can according that what need shape and features to stamping. Its advantage are high production rate, consistent and low cost. Its technology are apply in much industry such as automotive, heavy industry, Electrical and Electronics industry, electronic components, hardware fittings and Vehicle Accessories.FORESHOT could do: Design and development of continuous stamping、Stamping tool components、Design and manufacturing of continuous stamping tool、 various stamping metal parts、Sheet Metal、Sheet Metal Fabrication and Mechanical Parts.With Metal Stamping unit established for years, FORESHOT is continually upholding the attitudes of "client satisfaction" and "make our clients more competitive" to make efforts in development and product improvement. Therefore, to present our products are with the best quality and excellent service to our clients. The Metal Stamping Unit of FORESHOT was certified with ISO 9002 in 2000.

Insert Injection Molding

Insert Injection Molding could be called Insert Molding or Over Molding, which a sole part is formed using two or more different materials in combination. In Insert injection Molding can either be incorporated at the time of the molding process or can be inserted as post molding operation.Especially, if properly selected two kinds of material, it will obtain a strong bonding of the molded part. Therefore, the used of primers or adhesive was no longer required to achieve an optimum bond between two materials.This process of insert injection molding results in a strong bonded and integrated assembly with plastic encapsulated inserts.Insert molding made from the following material :Ceramic、Plastic、Metal and The substance that can withstand the high temperature of injection molding process.

Assembly Service

FORESHOT has great experiences from mold design to assembly service including SMT, PCBA, EMS, plastic product injection, precision plastic parts manufacturing, metal stamping, glue dispense, Ultra Sonic Welding, Ultra Sonic Parts Cleaning, and Product Packaging, With its consistent manufacturing flow service, FORESHOT enables the perfect realization of producing products from scratch for clients.

Double-Shot Injection Molding

Double-Shot Injection Molding uses plastic polymers to mold plastic parts with multiple colors, materials or components with complex designs in one mold and machine. Double-Shot injection molding allows versatility, is simpler and more cost effective in comparison to other processes.Double-Shot Injection Molding requires attention that strengthen of joint is one of critical issue to be considered.FORESHOT could use this technology to shorten the cycle time, assembly cost, human resource and turnover rate.Double-Shot Injection Molding apply in keyboard、Computer / Communication / Consumer Electronics、Electronic Components、Precision Components and Vehicle Accessories etc.

Top News

FORESHOT Received a Golden Award from SWISSCOM in 2025

FORESHOT Received a Golden Award from SWISSCOM in 2025Golden Award from SWISSCOM in 2025

Read More FORESHOT Received an Excellent Vendor Award from FOXCONN INDUSTRIAL INTERNET in 2025

FORESHOT Received an Excellent Vendor Award from FOXCONN INDUSTRIAL INTERNET in 2025Excellent Vendor Award from FOXCONN INDUSTRIAL INTERNET in 2025

Read More FORESHOT Got Greenhouse Gas Verification Opinion in 2024

FORESHOT Got Greenhouse Gas Verification Opinion in 2024Greenhouse Gas Verification Opinion in 2024

Read More