-

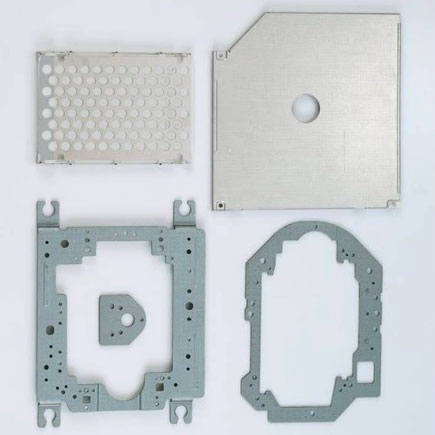

Metal Stamping

Metal stamping is an important manufacturing process its can according that what need shape and features to stamping. Its advantage are high production rate, consistent and low cost. Its technology are apply in much industry such as automotive, heavy industry, Electrical and Electronics industry, electronic components, hardware fittings and Vehicle Accessories. FORESHOT could do: Design and development of continuous stamping、Stamping tool components、Design and manufacturing of continuous stamping tool、 various stamping metal parts、Sheet Metal、Sheet Metal Fabrication and Mechanical Parts. With Metal Stamping unit established for years, FORESHOT is continually upholding the attitudes of "client satisfaction" and "make our clients more competitive" to make efforts in development and product improvement. Therefore, to present our products are with the best quality and excellent service to our clients. The Metal Stamping Unit of FORESHOT was certified with ISO 9002 in 2000.

-

Precision Injection Molding

Over the past few years, the demands for plastic injection products have seen considerable increase in consumer electronics products, transportation applications, medical supplies, etc. With the advanced development of precision machine and fast progress of plastic injection technique, progressing from general injection mold to micro injection mold manufacturing, the standards of precision and quality for the completed products of small Precision Components、Electronic Components、Computer / Communication / Consumer Electronics and Vehicle Accessories etc.. FORESHOT is dedicated to the development of precision plastic technique and processing, improvement of precision mold, and advancement of plastic object measurement technique, to provide its clients the products with high added value and competitiveness. FORESHOT using precise molds and advanced Sodick V-Line injection machine and JSW high-speed injection machine to produce and control each item in micro level.

-

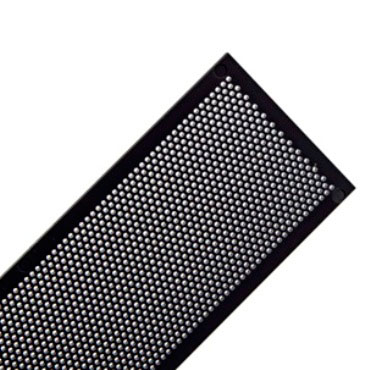

Double-Shot Injection Molding

Double-Shot Injection Molding uses plastic polymers to mold plastic parts with multiple colors, materials or components with complex designs in one mold and machine. Double-Shot injection molding allows versatility, is simpler and more cost effective in comparison to other processes. Double-Shot Injection Molding requires attention that strengthen of joint is one of critical issue to be considered. FORESHOT could use this technology to shorten the cycle time, assembly cost, human resource and turnover rate. Double-Shot Injection Molding apply in keyboard、Computer / Communication / Consumer Electronics、Electronic Components、Precision Components and Vehicle Accessories etc.

Top News

-

FORESHOT Received an Excellent Vendor Award from Leica in 2018

FORESHOT Received an Excellent Vendor Award from Leica in 2018Received an Excellent Vendor Award from Leica in 2018

Read More -

FORESHOT import automation system which can increase capacity

FORESHOT import automation system which can increase capacityIn order to provide high-quality products that satisfy customers, we have designed and developed a robotic intelligent production line dedicated to our customers' products.

Read More -

FORESHOT Received an Excellent Vendor Award from AVAYA in 2018

FORESHOT Received an Excellent Vendor Award from AVAYA in 2018Received an Excellent Vendor Award from AVAYA in 2018.

Read More