Metal Injection Molding

Metal Injection Molding, Tubes, Laser Cutting, Precision Machining

MIM is used to manufacture high-precision parts that can be used in fields such as medicine and dentistry.

In the medical and dental fields, MIM is used to manufacture high-precision parts such as surgical instruments, braces and implants made of biocompatible materials such as titanium alloys. These parts require complex designs and high strength, making MIM an ideal choice.

Metal injection molding combines the precision of plastic molding with the strength of metal to efficiently manufacture complex parts, making it ideal for the efficient production of small, complex components, typically weighing between 1 and 100 grams of metal.

Features

- The thickness range of the cutting tube wall depends on the laser power.

- Automatic feeding system, eliminating the need for manual labor.

- Equipped with intelligent digital controller, it has humanized control features. Easy to learn and operate.

- Special software design allows the operator to easily design the required graphics or text and then process them.

- Driven by servo motor, it has fast and smooth movements and precise positioning.

- Full-stroke pneumatic (double) chuck design doubles the efficiency.

Specification

- Plane processing range: Processing range: 500*600 mm

- Processing plate thickness: within 1.0mm

- Processing accuracy: ±0.01mm (accuracy depends on the actual drawing)

- Round tube processing diameter range: φ20mm

- Maximum processing thickness of round tube: 0.8mm

- Feeding length: 300mm

Applications

- MIM is used to manufacture high-precision parts for medical and dental products such as surgical instruments, braces and implants.

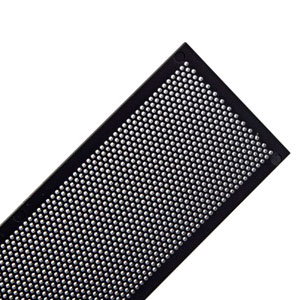

- Gallery

Top News

FORESHOT Received a Golden Award from SWISSCOM in 2025

FORESHOT Received a Golden Award from SWISSCOM in 2025Golden Award from SWISSCOM in 2025

Read More FORESHOT Received an Excellent Vendor Award from FOXCONN INDUSTRIAL INTERNET in 2025

FORESHOT Received an Excellent Vendor Award from FOXCONN INDUSTRIAL INTERNET in 2025Excellent Vendor Award from FOXCONN INDUSTRIAL INTERNET in 2025

Read More FORESHOT Got Greenhouse Gas Verification Opinion in 2024

FORESHOT Got Greenhouse Gas Verification Opinion in 2024Greenhouse Gas Verification Opinion in 2024

Read More